by ASHLEY MILLER

for the Sequim Gazette

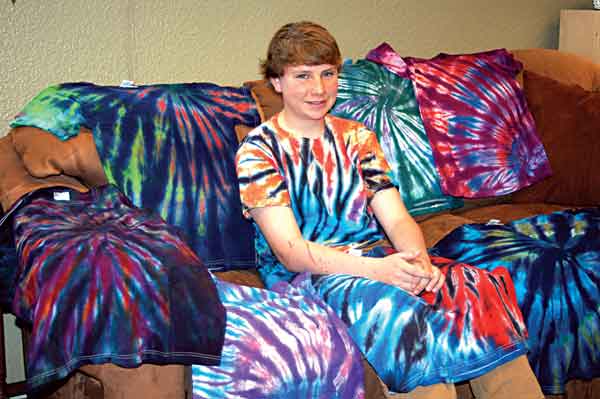

Camden Sukert’s personality is as colorful as the tie-dye shirts he makes and sells at the Sequim Open Aire Market.

Having just turned 13 years old last month, Camden is on summer break from Stevens Middle School in Port Angeles and will enter the eighth grade in September. He enjoys track, BMX racing and picking on his little sister and he wants to be a weather- man when he grows up.

Camden learned how to make tie-dye shirts in school four years ago. He enjoyed it so much — particularly the final step when he opens up a shirt and sees the unique design for the first time — that he started making them in bulk.

With his father’s support, Camden filed for a business license and applied to participate in the Port Angeles Farmers Market this year. When his request was denied, he approached the organizers of the Sequim Open Aire Market and was welcomed with open arms and enthusiasm.

On opening day in May, CJS Tie-Dyes was one of the biggest sellers, said Pat Sukert, Camden’s father.

“If my kid has an idea, I think that’s a good thing and I will always support him,”

Pat Sukert said.

“Not only is he earning some money but he’s a big supporter of the market and likes to buy something from everybody.”

Camden is putting most of his earnings into a savings account for a car when he turns 16 and college a couple years after that.

At the market, Camden offers a variety of tie-dye shirts in men’s, women’s and children’s sizes. Patterns range from traditional, hearts and swirls to reverse spider webs in at least 25 different colors.

In the future, Camden is thinking about adding infant “onesies” to his offerings and having a “tie-dye your own shirt” workstation for customers to try their hands.

The tie-dye process is fairly simple and a lot of fun, according to Camden. The steps include soaking the shirt in a special mixture, using rubber bands to twist and tie the shirt into sections, applying dye, placing the shirt in a plastic bag for three-five days, thoroughly rinsing the shirt in cold water and then washing the shirt with a special soap that sets the dye.

It’s advised, Camden said, to wash the shirt alone or with like colors for a few cycles afterward to prevent the dye from bleeding onto and ruining other clothing.

Though the creation process can be messy and gloves are advised, there’s no unpleasant or lingering smell.

These days, Camden makes about 10 shirts a week. As lavender season in Sequim fast approaches, he’s working on a variety of purple-colored shirts that are expected to be very popular.

According to Pat Sukert, tie-dye is “coming back into style” and “looks good with anything.”

“I haven’t seen anything that looks better than the shirts Camden makes and his are at least $5 or $10 cheaper than vendors we’ve seen at other markets,” he added.